Over the years, supply chain complexity has increased immensely. Companies have become more international and extended their customer portfolio, resulting in having to execute more activities. Subsequently, new or more complex processes are often introduced, which can result in a logistical nightmare, reflected in higher operational costs. For instance, a return process that is unnecessarily complex and adds no value for these companies. Therefore, Euro Pool System reinvented the return process in a way that reduces 'waste' and wasteful activities in the return chain and gives customers much-needed insights into their return logistics. This blog elaborates on this reinvented return process.

Reinvented return process for chain logistics optimisation

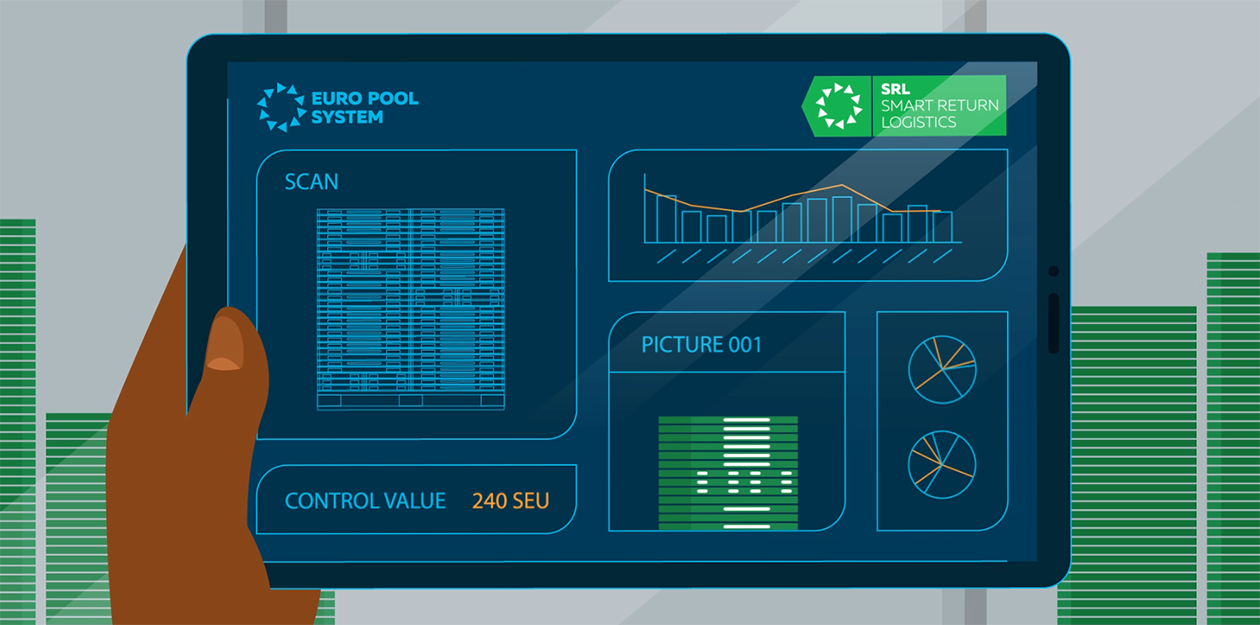

What started as an idea in 2016 to improve efficiency in the return chain, has grown in 2020 into the standard for 47% of the total volume of trays EPS receives from customers. This idea is better known as Smart Return Logistics (SRL) or in other words the transition to what we call 'full mix unsorted': the possibility to return different tray types on one load carrier. With SRL organisations can reduce their working capital by making the need for sorting on site obsolete. However, this is only a small part of the added value offered by the SRL program. The digital footprint that is captured can maximise the understanding of a company's return business. Furthermore, we expect volume growth in smart return logistics in the coming years, which is in itself interesting.

What is the impact of SRL on your operational process?

Assuming that a company is not using the SRL program yet, dirty trays are returned sorted per tray-type on a load-carrier. As a result, this company has a work-in-progress stock for the trays that need to be returned to Euro Pool System until it meets the agreed-upon quantity per load-carrier. With SRL, this is reduced to a full mix load-carriers, and by doing so:

- work-in-progress stock will be reduced

- operational m2 needed for return activities go down

- sorting activity isn't needed any longer

Next, these full mix load-carriers are brought to EPS. At this point, we can give insights into the content of the load-carrier, with state-of-the-art vision systems. This data can be shared with the customer's ERP system and a load-carrier summary will be made available in the portal, so the customer will be able to check the pictures that were made of the load-carrier in a transparent manner.

Getting insights into your digital footprint

Every load-carrier is registered with a Serial Shipping Container Code (SSCC), this is the unique code for the return of a load-carrier to EPS. With this SSCC all whereabouts of the load-carrier can be captured. For example, it can be that one needs to steer on efficiency within the return chain and need insight on DC or shop level.

Performance review is a strong tool to improve the operational process. Euro Pool System can support customers in this review by providing insight on how to reduce “waste” in the return chain:

- Fill rates, to ensure that the load-carrier meets the expected quantities for efficient use of transport.

- Anomalies, to smoothen the operational process, taking out “waste” in the return chain.

Furthermore, SRL ensures a deep understanding of the return chain by giving insights in:

The downstream dwell time

It is vital to know the slow movers, as the operational focus needs to be there. It can be a congestion that requires operational action. Without SRL one would normally notice this later on.

Clear balance on what is sent and received

You need the insight that all send load-carriers are also received by EPS. This needs to be in balance. Imbalance means load-carrier are lost. In case of imbalance, one needs to know the latest whereabouts of these load-carriers.

One of the main challenges faced by supply chain managers is to how fully utilize the digital footprint left in the return-flow. As explained, SRL provides a powerful toolkit to use this digital footprint and to drive efficiency in our return chain. Smart return logistics can be implemented on a basic level, in which the coverage of the digital footprint is limited, or you can decide to capture the full digital footprint of the return chain. This heavily depends on how data driven the organisation is and the value one wants to take from the SRL implementation.

Are you interested in which SRL set-up best fits your organisation? We can provide you with tailored advice. Do not hesitate to get in touch with us: