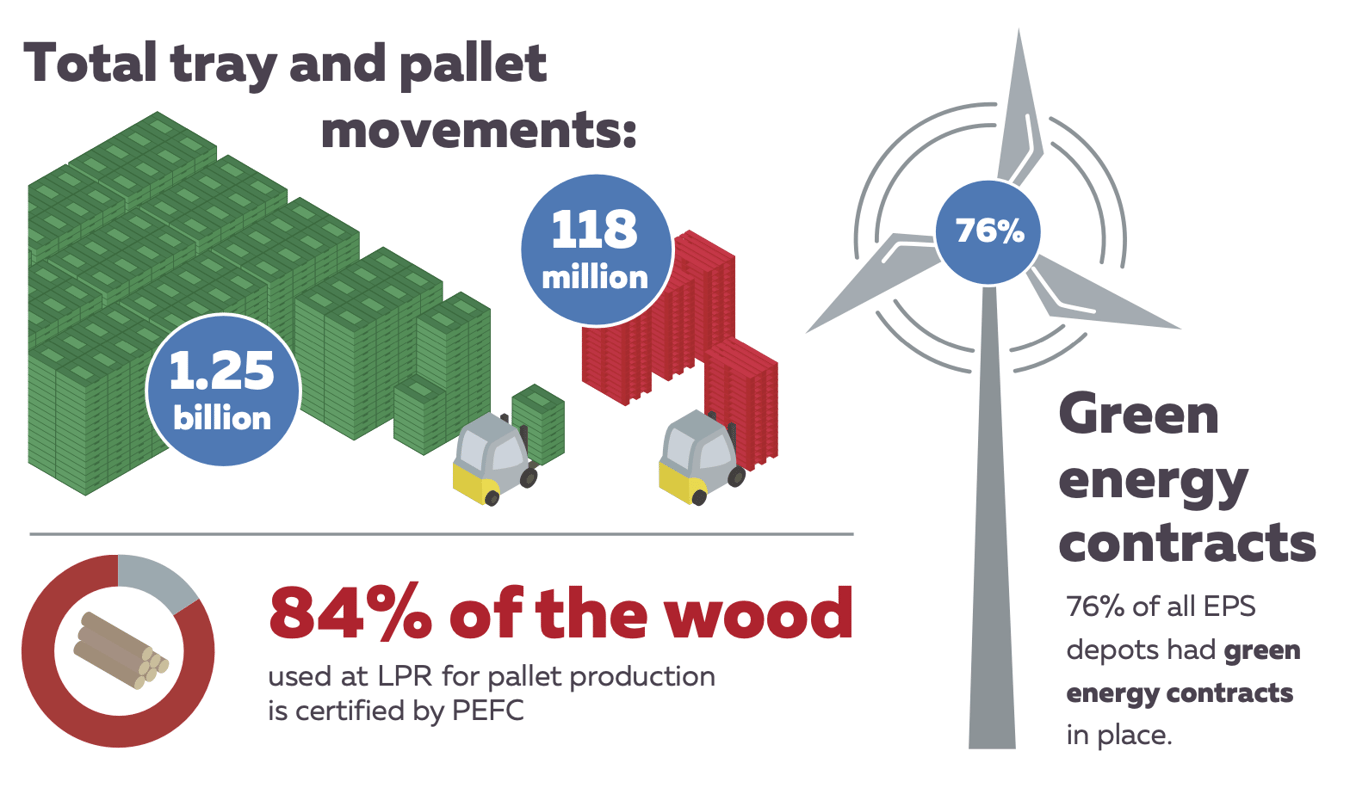

At EPS, we are fully committed to using green energy and have extended and maintained our contracts to ensure that our locations are powered by renewable sources. While this does entail some additional costs, we see it as a worthwhile investment to ensure that the energy we consume is green. Currently, around 80% of the locations where we handle energy contracts are using green energy. This resulted in a CO2 reduction over 9.000 tonnes, which means that we are close to our goal of running 80% of our depots on green energy. It is important to note that for the remaining depots, green energy contracts are not always available, or the depots are located on our customers’ sites.

At LPR, we are also working towards increasing the use of green energy in our service centres. We are happy to report that we have installed solar panels at our external service centre in Portugal and have switched our energy contract to a green supplier. By 2025, our goal is to run all our service centres on green energy.

At LPR, we are also working towards increasing the use of green energy in our service centres. We are happy to report that we have installed solar panels at our external service centre in Portugal and have switched our energy contract to a green supplier. By 2025, our goal is to run all our service centres on green energy.