Onze gestandaardiseerde verpakkingen maken het mogelijk om logistieke processen in de gehele keten te automatiseren. Bovendien zorgen onze klapkratten voor optimale efficiëntie, omdat ze 86% minder volume innemen gedurende retourtransport.

Laatste nieuws en hoogtepunten

COVID-19 UPDATE

-760-504.jpg?width=167&height=94&name=Kesgro-DSC_5969-rode-pallets-HR-(2)-760-504.jpg)

Euro Pool Group is strenghtening the circular economy

New rail link for fresh produce enormous boost for sustainability

How to save 60% more CO2 in the fresh supply chain?

Reusable plastic boxes generate less environmental impact than disposable cardboard boxes

Increasing the sustainability of the European fresh supply chain through reusable packaging

Ontdek de wereld van de circulaire verpakkingen

Euro Pool System is de toonaangevende logistieke aanbieder van herbruikbare verpakkingen in de Europese versketen. Met onze herbruikbare klapkratten optimaliseren we niet alleen uw keten, maar bouwen we ook aan een duurzame toekomst.

Efficiënte logistiek

Kwaliteit, veiligheid en hygiëne

Aan het einde van elke roulatie worden onze kratten grondig gereinigd volgens een strikt wasproces. Met onze herbruikbare klapkratten optimaliseren we niet alleen uw keten, maar bouwen we ook aan een duurzame toekomst.

Productbescherming

Onze herbruikbare kratten zijn zeer stevig en bieden uw producten optimale bescherming tijdens het transport. Dit resulteert in aanzienlijk minder productverlies in vergelijking met alternatieven voor eenmalig gebruik.

Service/partnerschap

Door onze lokale aanwezigheid zijn we altijd dicht bij u in de buurt. Door ons grote logistieke netwerk kunnen we verbinding maken met partners door heel Europa.

Duurzaamheid

Onze herbruikbare kunststof kratten hebben een gemiddelde levensduur van meer dan zeven jaar en zijn daarom vele malen duurzamer dan verpakkingen voor eenmalig gebruik.

Op naar een duurzame versketen - we doen het samen

Onze diensten helpen u om uw ecologische voetafdruk aanzienlijk te verkleinen. Met onze herbruikbare en opvouwbare kratten, logistieke diensten en efficiënt gebruik van middelen helpen wij u uw duurzaamheidsdoelstellingen te bereiken. Ontdek welke impact u kunt maken.

Onze pooling oplossingen

Euro Pool System biedt een unieke combinatie van logistieke diensten en herbruikbare verpakkingen binnen Europa, op basis van verhuur en retournering.

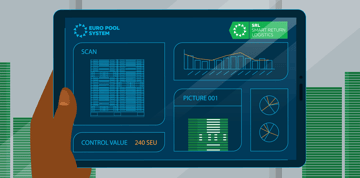

Euro Pool System service centrum

Wij bieden een complete pooling service waarmee we ervoor zorgen dat u altijd de juiste kratten in perfecte staat ontvangt. Wij opereren vanuit onze wijdverspreide service centra door heel Europa.

Geïntegreerd service centrum

Wij bieden u de mogelijkheid om onze activiteiten te integreren in uw distributiecentra. Dit betekent dat kratten direct naar u geretourneerd worden. Deze integratie maakt uw versketen efficiënter en elimineert onnodige transportkilometers. Dit resulteert bovendien in een aanzienlijke CO2-reductie.

Retourlogistiek distributie centrum

Wij beheren uw complete keten van begin tot eind, en weer terug. Dit doen we door hergebruik, recycling en het beheer van alle retourtransport artikelen rechtstreeks vanuit uw distributiecentra.

Inzichten van onze experts

Actuele inzichten leest u in onze blogs en nieuwsberichten.

Alle artikelen